服务咨询热线

18660980818

临沂宏森轨道交通材料有限公司

手 机: 18660980818

邮 箱:sen@zkjddz.com

网址:www.hsforge.cn

地址:高新区罗西办事处沙埠庄村

Tolerances and allowance for die forgings

在模锻过程中,由于坯料在高温条件下产生表皮氧化、脱碳现象,导致锻件表面质量不佳,甚至产生其他缺陷;由于坯料体积变化及终锻温度波动,使锻件尺寸控制不定;由于锻件出模的需要使锻件侧壁添加敷料;由于型槽磨损和上、下模难免的错移现象,导致锻件尺寸出现偏差等。所有这些原因使锻件不仅应有机械加工余量,而且还要规定适当的锻件尺寸公差。

In the process of die forging, the surface quality of forgings is not good because of the oxidation and decarbonization of the surface of billets at high temperature, and even other defects are produced. The phenomenon of misalignment of the upper and lower die is unavoidable, resulting in the deviation of forging size. All these reasons make the forging not only have the machining allowance, but also have to specify the appropriate size tolerance of the forging.

锻件上需要机械加工的部位,都应给予加工余量。此外,一些重要的承力件,要求100%取样试验或者为了检验与机械加工定位的需要,还应给予必须的工艺余块。

The machined allowance should be given to the parts that need to be machined on the forging. In addition, some important load-bearing parts require 100% sampling test or necessary process residue for inspection and machining positioning.

在实际模锻生产中,由于受到各种工艺因素的影响,锻件的实际尺寸不可能与公称尺寸相等,无论在高度方向还是水平方向尺寸都会有偏差,因此对锻件规定允许有一定限度的偏差范围。锻件大尺寸大于锻件公称尺寸的部分为正公差,锻件小尺寸小于锻件公称尺寸为负公差,。

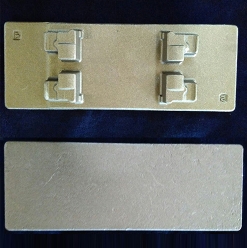

In the actual die forging production, due to the influence of various technological factors, the actual size of the forging can not be equal to the nominal size, whether in the direction of height or horizontal dimension will be deviated, so the forging provisions allow a certain range of deviation. The part whose maximum size is larger than the nominal size of the forging is positive tolerance, and the minimum size of the forging is smaller than the nominal size of the forging is negative tolerance, as shown in the figure.

制订锻件的公差和加工余量根据JB3834—85标准所规定的原则,应考虑下列因素:

According to the principles stipulated in JB3834-85 standard, the following factors should be taken into account in formulating tolerances and machining allowances for forgings:

1)公差等级:公差分为两级,普通级公差是指按一般模锻方法能达到的精度公差;精密级公差是有较高的尺寸精度,适用于精密锻件。

1) Tolerance grade: Tolerance is divided into two levels, common tolerance refers to the precision tolerance that can be achieved according to the general forging method; precision tolerance has a higher dimensional accuracy, suitable for precision forgings.

2)锻件质量:锻件质量根据锻件图的名义尺寸进行计算,并按此质量查表确定公差和余量。

2) Forging quality: Forging quality is calculated according to the nominal size of the forging drawing, and tolerances and allowances are determined according to the quality table.

3)锻件形状复杂系数:锻件形状复杂系数S是锻件质量m锻与相应的锻件外廓包容体的质量mc的比值,即:S=m锻/mc。

3) Form Complexity Factor of Forging: Form Complexity Factor S is the ratio of the forging mass m to the mass MC of the corresponding outer contour of the forging, that is, S = m forging / mc.

4)分模面形状:分模面形状分为两类:一是平直分模面和对称弯曲分模面;二是不对称弯曲分模面。

4) Dividing surface shape: Dividing surface shape can be divided into two types: one is flat dividing surface and symmetrical bending dividing surface; the other is asymmetrical bending dividing surface.

5)锻件材质系数:锻件材质系数分为两级:M1和M2。M1是钢的最高含碳量小于0.65%的碳钢或合金元素最高总含量小于3.0%的合金钢。M2是钢的最高含碳量大于或等于0.65%的碳钢或合金元素最高总含量大于或等于3.0%的合金钢。

5) forgings material factor: forgings material coefficient is divided into two levels: M1 and M2. M1 is a steel with a maximum carbon content of less than 0.65% or an alloy steel with a maximum total content of less than 3.0%. M2 is an alloy steel whose maximum carbon content is greater than or equal to 0.65% of steel or whose maximum total content of alloy elements is greater than or equal to 3.0%.

6)零件的机加工精度:JB3834—85标准适用于零件的表面粗糙度大于Ra1.6。若表面粗糙度小于Ra1.6,其余量应适当加大。

6) machining accuracy of parts: JB3834 - 85 is applicable to parts whose surface roughness is greater than Ra1.6. If the surface roughness is less than Ra1.6, the remaining amount should be appropriately increased.

模锻件厂家就选临沂宏森轨道交通材料有限公司主营大型模锻件 卡车前轴